This post may contain affiliate links.

I dropped a teaser about this a few weeks ago, so now it’s time I finally came clean with all the details. Since that time, a number of folks at Winnebago’s Grand National Rally, and on the Lake Superior Adventure have seen Lance in action, so some of this has already leaked out. That’s OK, it’s all pretty cool stuff.

But most people seemed to be more interested in the curtains I made than in the state of the art power system. I found that strange…

I had been thinking about a system like this for a long time. My interest with it probably began when we visited Advanced RV in Ohio. These days, there are lots of people adding lithium batteries to RVs. Advanced-RV has been doing it for a while now, and their installs work very well, from all reports. They approach RV power as an integrated system (rather than just installing a bunch of parts and hoping for the best). They put a lot of work into that integration, and I think their success is due to that. I wanted to emulate this systems approach when upgrading our RVs power.

System Goals

I had two major goals here. The first one was the same as many people: I wanted to do away with the generator. In our case though, it wasn’t because the generator was loud. (OK. I mean, yes, it was loud, but we could deal with that.) It had more to do with the fact that after almost a year, we had only 13 hours on the generator – and 10 of them were just to exercise it. Exercising the generator was pretty much the whole reason I added an auto-generator-start module. So from a usage perspective, the generator was a big “meh”.

The other strike the generator had against it was its unwillingness to start at higher altitudes. I’m thinking of our trip to the Fishlake National Forest in central Utah. At 9000 feet, the generator just refused to start. We didn’t actually need the generator, we just wanted to see if it would start (and we could hear a Honda 2000 not too far away). I know there are carburetor kits for high altitude that would have helped. But a couple months later, we were camping on the beach in California at sea level. Considering where the generator was mounted, messing with the carburetor as we changed altitude seemed like a real pain for something we barely used.

Our Winterproof Travato at 9000 feet. All systems go – EXCEPT THE GENERATOR…

The other major goal I had was that I really don’t want to think about it too much. We all know I like to tinker with the RV, but after reading about lithium batteries and inverters for the better part of two years, I’m over it. I want things to work without my having to constantly monitor and tweak them.

Now, that doesn’t mean I don’t have a healthy curiosity in the data and the results. But you may be disappointed in this post if you’re expecting to read things like:

“By decreasing the float voltage from 13.6 to 13.4 volts, I was able to increase the remaining capacity at one year by 3.2%. This translates to an increased lifespan of 4398 full discharge/charge cycles – up from 4261. Those extra 137 discharge/charge cycles will likely be an even greater number since I never let my batteries get below 84.9% full or experience temperatures above 90 degrees Fahrenheit. ”

So, fair warning to battery purists: don’t gasp in horror as you read about me deliberately draining the expensive battery until the coach went dark. (Yes. I did. And it was awesome.)

System Design

Given my aforementioned apathy toward battery capacity and charging system discussion, it won’t come as a surprise that I let someone else design the system for me. (I’m an aerospace engineer – not electrical!) In this case, it was the good folks at Xantrex (a division of Schneider Electric) who did the heavy lifting on the design side. I can’t say enough good things about the system they’ve put together.

They took the lead in contacting suppliers of components that were already on the market and working with them to gather information, size components, adjust parameters, work out communication protocols, and basically make sure everything would work together as a system when it was all said and done. Though the components were all sourced from different vendors, they’ve so far worked together flawlessly. All they’re missing is a catchy name. So just pick one word from the first column and one word from the second, add them together, and let’s pretend that’s the name. (I’m going with “Amp-Camp”!)

If this sounds like your marketing department… I’m really sorry.

But the folks at Xantrex didn’t stop at just designing the system and sending me a parts list. They actually showed up at FitRV HQ and helped me install and remove stuff. This was a good thing. Since the amounts of stored electricity we’re talking about can be potentially harmful, I was glad to have the assistance and extra eyes for safety.

They even helped me drop the generator when it was all over!

The system they put together consisted of the following components.

Second Alternator for the ProMaster

This proved to be the most difficult and cautionary piece of the whole puzzle, mainly because this involves messing with the engine of your ProMaster. I’m good with wood, and OK with electrical and plumbing, but I’m no mechanic. So I had to find help to install this – hopefully without blowing up my warranty. Fortunately, the team at Larry H. Miller Dodge in Sandy, UT agreed to take on the task.

The alternator kit is already used in other ProMaster based RVs. It comes with everything you need to complete the installation. Here is the kit as I unpacked it on my bench and immediately decided there was no way I was going to mess with it.

When I got to step 1, I knew I was in over my head.

The installation is pretty involved. You have to drop the air conditioner compressor, install a pulley; install a bracket; add the second alternator and belt and tensioner; cut and re-route coolant hoses, and somehow get it all back together. Here’s what it looked like halfway through, with the bracket installed and the compressor hanging loose.

And when it’s all done, it looks like this.

It took a whole day to get it installed, and I was pretty happy with the results for about 50 miles. Then this happened.

While heading up Parley’s Canyon toward Park City, Lance’s dash lit up like a Christmas tree, and things severely overheated pretty much all at once. We made it up (barely) and coasted down the other side to wait at a gas station until we could get a tow.

What had happened was that the new hose and belt routings were just a bit too close to each other. The belt, after 50 miles or so, cut through the radiator hose, and spewed all the coolant onto the freeway. Boom! Instant overheating.

Fortunately, the crew at Larry H. Miller Dodge are real stand-up folks. They owned the problem and fixed it at no additional charge. They also took ownership of the next two problems which had Lance leaking coolant: a warped thermostat housing, and a damaged water pump. They fixed these as follow-on issues to the original mistake. So, other than having to go back and forth to the dealership a few more times than I had planned, it all worked out well in the end. Since then, we’ve put about 2000 miles on Lance, and everything has held up, so we’re pretty confident that all those problems are behind us.

This alternator also came with a voltage regulator attached. This is a key part of the system, and it does two things. First, it ensures that the alternator’s output is properly matched to the lithium batteries. This is a problem for single-alternator systems. The chassis alternator is designed to charge the starting battery, but that charge profile likely isn’t optimal for the house batteries – especially if they’re lithium. So by having a second alternator with a properly regulated output, the lithium batteries can have it their way, and the rest of your chassis electronics can have it theirs. Everyone is happy.

The second important feature of the voltage regulator is that it has a control circuit on it which will allow the NeverDie Battery Management System (BMS) on the Lithionics battery to “turn off” the alternator when it decides it’s full. This did require running a control wire from the battery to the voltage regulator, but it works – I’ve seen it in action. Working out that bit of communication is why I was glad to have Xantrex designing the system for me. It’s not likely that, as an individual, I could have worked that out between the three suppliers involved.

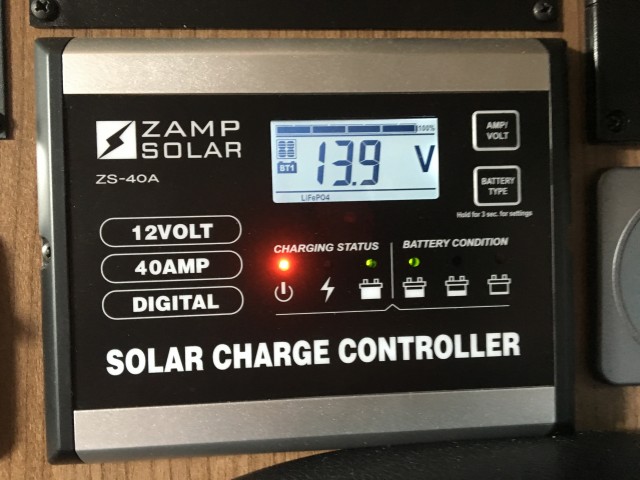

Zamp Solar Charge Controller

Our Travato was already sporting 300 watts of solar panels connected to a Zamp solar charge controller. But that controller was programmed for AGM batteries, which require a different charge profile than our new lithium battery.

Fortunately, Xantrex had been working with the people at Zamp as well. In the year since we purchased our Travato, Zamp had already come out with a lithium-ready controller. But Xantrex had worked with them further to tweak the charge profile to match the other components in the system. When receiving power and set for lithium, the Zamp system delivers bulk and float charges as specified by Xantrex (14.6 and 13.4 volts, respectively). As a bonus, this new charge controller will handle 40 amps as opposed to the previous 30.

Lithionics Battery

This battery is what really makes all this possible. It’s a 420 Amp Hour battery from Lithionics, with an on-board battery management system. It’s a lithium battery, which brings some special considerations.

I had always been worried, when thinking about lithium batteries, about the potential for damage from the cold. You see, lithium batteries can be damaged by charging them at temperatures below freezing. Since we like to take our RV out in cold weather, and since the stock battery and generator locations in our Travato are underneath the body of the van, this was a problem. I had assumed that we’d be using the generator mounting location for this battery, and was thinking of heating blankets, insulation, and whatnot.

The Xantrex guys actually thought up this mounting location, and we’re glad they did. We lost one drawer of storage in the pantry, but what that bought us was automatic climate control for the battery for zero effort or expense. It’s genius, and similar to how I passively heat the water lines in the winter.

This did require a bit of cabinet modification, and some angle aluminum that I riveted together to keep things from moving when underway. Also, this battery has two user-operated button controls, which I mounted on the cover I had to build.

The control with the lit circle is the master battery on/off switch. It comes in very handy when you’re working on the RV and get nervous about the rather large energy store on your 12 volt system. This is different from the Winnebago-installed coach master switch because this one just controls this one battery. With this switch off and the coach switch on, for example, you would still have power from solar (assuming the sun is out). It’s kind of interesting, and I promise you’ll only forget the difference between the two once…

The second button is the “reset” switch. I only need it when I drain the battery to the point where the BMS shuts things down. This button is how you get your battery and electrical system “booted up” again. Yes, I’ve done this already. We’re getting to that.

And, since I’ve mentioned it a few times, let’s discuss the on board NeverDie BMS. It protects against overcharging, over discharging, and a host of other things. But it’s mainly those first two I’m concerned with. I’d mentioned before that it has a circuit that is tied to the voltage regulator on the second alternator. It does, and it’s the BMS that decides “I’ve had enough charging, thank you,” and kills the alternator. That keeps the battery from facing massive overcharging on a long road trip, for example.

On the discharge side, the BMS prevents running the battery all the way into the ground. It shuts down the battery when it’s about 90% discharged. Yet it retains enough reserve charge in the battery that it can be re-booted, as I mentioned above.

Xantrex Freedom SW Inverter

Naturally, Xantrex designed the 120 volt side of things around their own inverter, the Freedom SW 3012 with their System Control Panel. This is a true sine wave inverter with a 3000 Watt continuous output and a surge current rated at 80 amps. It’s a beast of an inverter/charger, but fortunately, it fits in the space where the previous Magnum inverter lived.

The 80 amp peak rating is the key driver here, as it will reliably start the air conditioner in our Travato. That air conditioner has a “Locked Rotor Amps” rating of 63, which represents the peak cold-start load. With a rating well above that, the Xantrex inverter has started our air conditioner many times now without complaint.

Beyond that, the Freedom SW is also a charger, which eliminates the need for the converter, and so we removed it, along with the transfer switch. The other thing to note is that Xantrex has updated the software in their inverter to work properly with lithium batteries. They updated the inverter on the fly using the ports on it, so we have the very latest revision.

Coleman Mach 10 Air Conditioner

Let’s talk about the elephant in the room. This is what it’s all about! When everyone talks about using large lithium batteries and large inverters in their RV, all they really care about is powering the air conditioner. Anything else you typically run in an RV can get by with much less battery or inverter capacity. The success of any RV power system is going to be measured by how long it can run an air conditioner.

With this in mind, some time ago, we had swapped our Coleman Mach 8 air conditioner for a Mach 10. Besides being just a hair taller, the Mach 10 runs at only 12-13 amps (@120v) versus the 15-16 amps the Mach 8 is rated for. When you’re trying to squeeze all the performance you can out of your batteries, those 2-4 amps matter, because they translate to 20-40 amps at 12 volts. That’s a 60 to 120 Amp-Hour savings over 3 hours, which is huge.

Our goal with the battery and inverter setup is to run the air conditioner for three hours without having to run the vehicle. Three hours represents the longest race I typically compete in (during which Stef might be stuck hanging back in the RV). It’s also about an hour longer than we ever ran the generator at once during our first year in the Travato. After three hours, we’d be fine to run the engine for a while to recharge.

One additional benefit of the Mach 10 vs the Mach 8 is that it’s approximately 50 billion times quieter*. The reduced volume is very noticeable on the outside, but not so much when you’re trying to sleep 18 inches from the air distribution box inside.

* Claim is pure hyperbole, and not verified.

Wiring and Monitoring

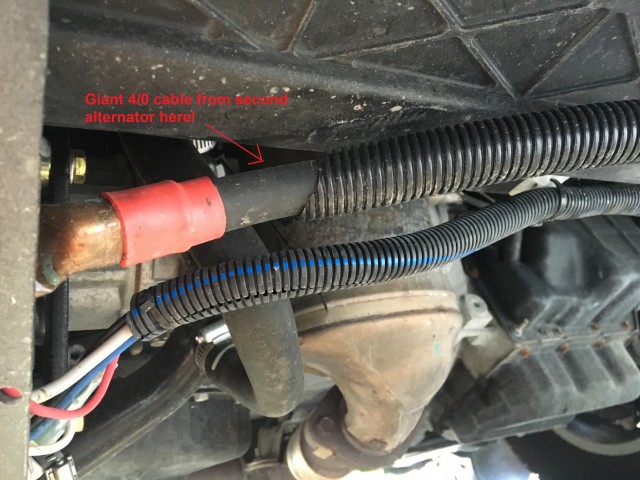

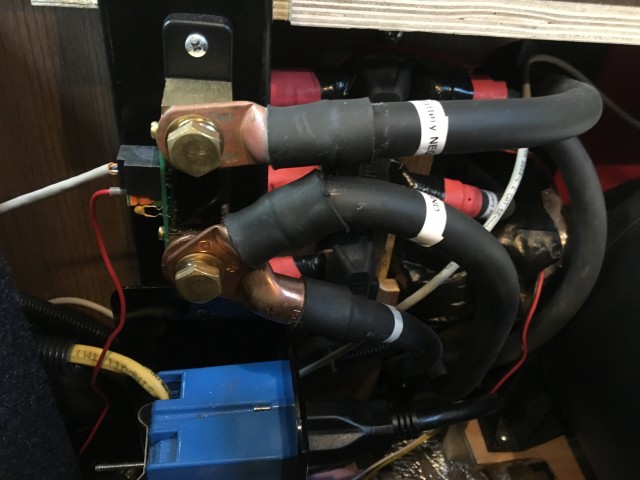

We wired all of the high-amp runs in the van with 4/0 welding cable, and used 300 amp fuses where appropriate. This is thick copper, and with the battery at mid-ship, none of the runs are super long, so I’m not worried about any voltage drops. Also, the welding cable is extremely flexible, so we had no difficulties in fishing it where it needed to go.

And have a look at that! To me, it looks something like what I imagine the first electric chair looked like. But what I do want you to notice is the presence of the shunt, which is part of what provides extremely accurate battery monitoring via this:

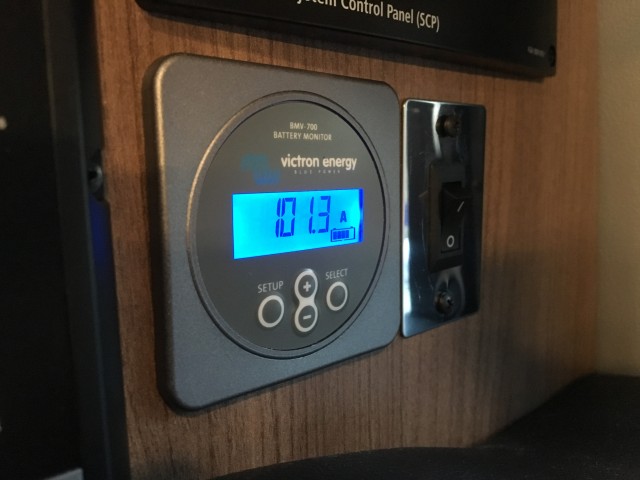

Our monitoring needs are met by this Victron battery monitor. I’m a big fan of hyper-accurate battery monitoring. If you’re going to monitor the battery, you might as well do it right. I installed a Trimetric in Das Bus. Our Magnum setup also had a shunt-based battery monitor, and now we have this Victron.

In addition to the basic amps in/amps out monitoring, it also gives state-of-charge (SOC), and estimated runtime based on the current load. I’ve also set it to alarm at 10% of usable capacity remaining.

The other item we have is this switch.

This switch performs a very important function: it keeps the two 12 volt electrical systems (chassis and house) separate. You see, from Winnebago, the house and chassis batteries are connected when either of two conditions occurs:

- The engine is running.

- The “Battery Boost” switch is pressed.

With a highly regulated lithium battery setup, I pretty much NEVER want the first condition to connect the batteries. But I may one day briefly want the second. This switch interrupts the circuit that activates the solenoid at the rear of the coach that connects the batteries. As long as the switch is off, the batteries will never be connected. If the switch were “on”, the two electrical systems could be connected and I could then use the boost switch.

There is also the potential that if one or the other of my alternators fails, I could turn on the switch and run both the vehicle and house with the other alternator. It’s kind of like a weird backup alternator. I don’t know if I’d ever do that unless it was a huge emergency, but it’s interesting to think about. Realistically, what I’ll probably do is put some sort of covered missile-launcher-style switch there instead so we never accidentally turn it on.

The Electric Travato in Daily Use

So when you hook all this stuff up, how does it run, day to day? In a word, fantastic! In normal use, you really never need to pay much attention to things, so if you’ve been overwhelmed reading this far, never fear. About the only thing you really need to know is which button to push to turn the inverter on and off. I’ve taught Stef which one it is, so life is good.

The new inverter has the Stef Seal of Approval

We’ve tried things like running the rear air conditioner while driving. That works just fine, and we’re still charging the battery when we do. The one problem we did encounter was traveling across Montana in 100+ degree heat. After running the rear AC from the inverter for a few hours, it got pretty hot cooped up in its little cabinet. Eventually, it shut itself down. But five minutes later, it turned back on again and everything was humming along. It was a pretty graceful recovery in my opinion. I’m considering some sort of venting for that cabinet – but it’s not a high priority since it only happened one time under extreme conditions.

I’ve run the inverter all day while I worked and Stef drove. No problems encountered, and I have no concerns about running the inverter hard for extended periods.

We’ve run the microwave and the air conditioner at the same time from the inverter, and that worked just fine, too. In the event we ever really did start using lots of juice, the EMS built into the coach by Winnebago would shut something down before we got into trouble, if the inverter itself didn’t stop the foolishness first.

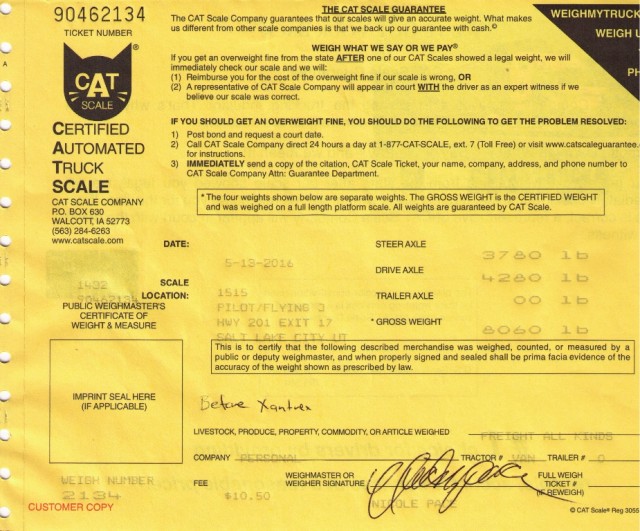

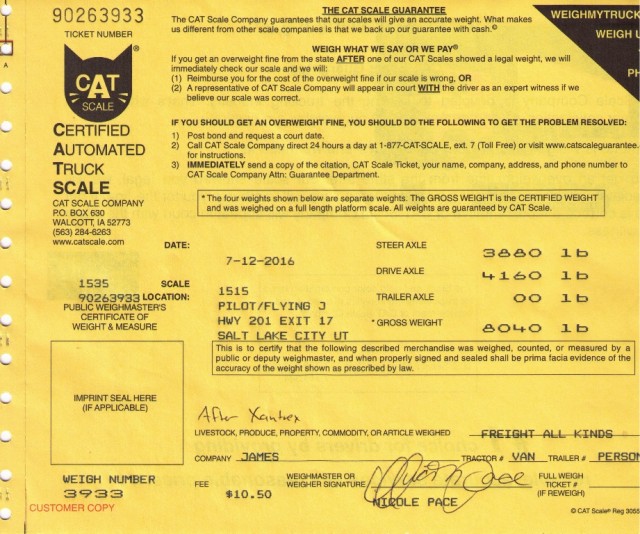

I did weigh the RV before and after. There was not much change. Here we are “before”. But remember, I already had a smaller inverter installed.

And here’s the weight after. 20 pounds lighter overall, and some of that weight shifted forward a bit.

In the big scheme of things – that’s not much of a change, weight wise. We lost the generator, converter, transfer switch, and two AGM batteries. We added a big battery, a larger inverter, and quite a bit of 4/0 cabling. I would have thought the weight would have changed more.

As far as charging, without paying much attention to it, the batteries stay pretty close to full the entire time we use the rig. The combination of solar and driving keeps us pretty topped off. So I’m well on my way to meeting that “don’t pay much attention to it” goal. And I think Stef’s already there.

Some Actual Testing Results

All right, all right. What fun would it be if I didn’t share some real numbers and results? The litmus test of this whole thing is “how long can it run the air conditioner?” So let me get this out of the way.

3 hours and 19 minutes.

Here are the particulars of the test:

- Outside Temperature: 88-82 degrees

- AC Run Time: 3 hours 19 minutes (Some cycling of AC in second hour and after. But never less than 80% duty cycle even in those hours.)

- During this time, 2.6 Amp-Hours were contributed by the Zamp solar system. (I had parked in the shade to keep that to a minimum.)

- Ending event: Lithionics BMS shutdown. The coach went completely dark.

- Voltage was 11.87 Volts according to the Victron monitor approximately 10 minutes before shutdown. I didn’t catch it right at shutdown.

- Amp-Hours extracted: Greater than the 377 AH drawn from battery according to Victron monitor approximately 10 minutes before shutdown.

So basically, the BMS called the show over with just less than 10% of charge remaining, as expected. I’d like to be able to say I was surprised about something here, but everything worked exactly as advertised.

Restarting the coach from that dark state was very simple. I plugged in the coach. Everything is still dark at that point, because with the battery off, the inverter/charger didn’t recognize that there was anything to charge. Then a quick press of the reset button, and everything lit up and the battery started charging. It’s a good thing that the BMS leaves itself a little room to restart on shutdown. I suppose I could have attempted the startup with the engine and second alternator running instead, if shore power was not available.

During this test, the Victron battery monitor was very accurate as it counted down, both in time remaining and in percentage. Both of those hit zero just before the shutdown event. And it alarmed at 10% of usable capacity remaining just as programmed. If I hadn’t been determined to see how far I could go, I would have applied some charging when that alarm went off.

But besides that one test, here are some other data points for those who want to know.

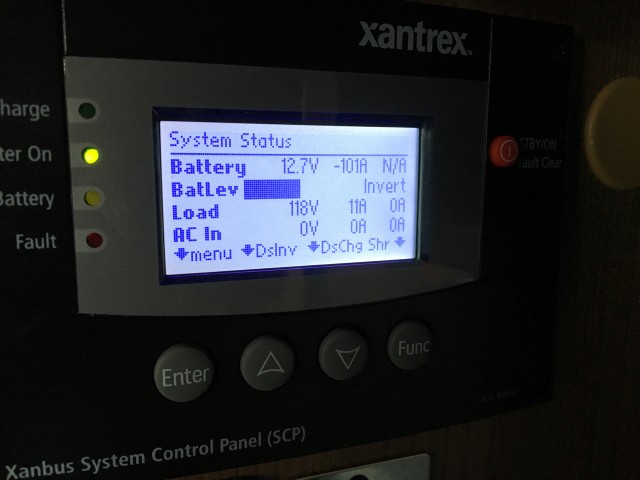

The Coleman Mach 10, running through the Xantrex inverter, burns 11amps AC, which translates to 101 amps DC, according to the Xantrex Control Panel. I would have said 102 ((118 x 11)/12.7), but whatever.

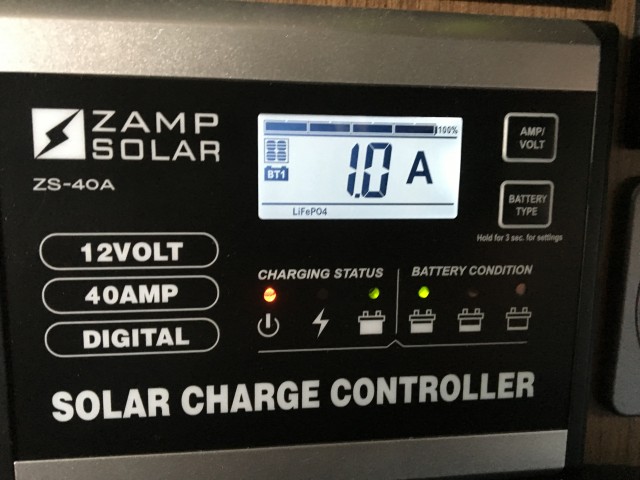

When I took this picture, the Zamp solar charge system was contributing about 1.0 amps. (Again, parked in the shade.)

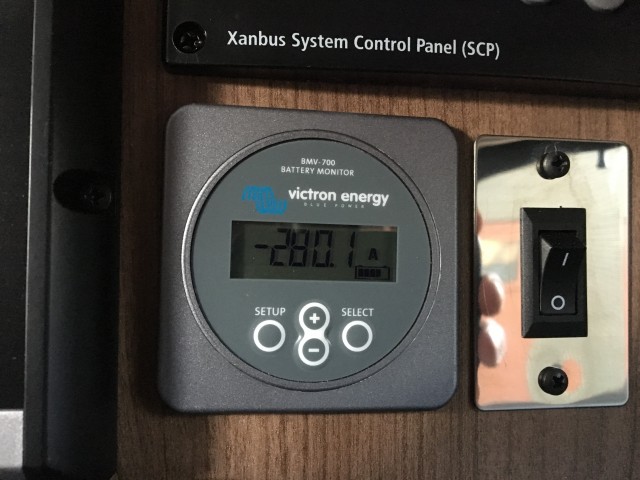

The battery monitor at this moment was showing 112.5 amps going out of the battery

So with a little math, we can calculate: Amps out of the battery + Amps Contributed by Solar – Inverter Output – 2.5 amps for lights, etc = losses. 112.5 + 1 – 101 – 2.5. I come up with 10 amps of losses when running the AC. With just the inverter on and no AC running, it uses about 3.8 amps. So all that means, it would seem, is that the system is over 90% efficient. Xantrex only claims 90%, so it seems they’re actually better than they claim.

I’ve mentioned that we’ve run the microwave and AC with no problems. But just to see how far I could push it, while the air was on, I plugged in an 1800 watt induction cooktop and turned it up to 10. Besides boiling water in 90 seconds, I got a peak of 280.1 amps being drawn down from the batteries!

That’s a crap-ton of juice. All the other loads are minor compared to the air conditioner and that cooktop, and I’ve already written a post where I explore the other 12 volt loads in the coach, so that’s as far as I’m going on the load side for now.

On the charging side, when the Xantrex is plugged in, it delivers its programmed 100 amps to charge the battery.

OK. OR, 101.3 amps. Slightly weird, but whatever.

With the Xantrex unplugged, and the alternator running at idle, I get 172.6 amps in.

That’s not quite the 280 amps at idle in the brochure, but it’s pretty darn good.

And if I rev up to 2000 rpm, we get this for a charge from the second alternator:

And finally, if I need to charge the batteries in a big hurry, I can always power the Xantrex charger and run the engine. When stacking this way, at idle, I get a pretty substantial charge of 234 amps from the two combined. If I rev the engine, the charge seems to peak at about 250 amps, and it won’t easily go higher. I suspect there’s a limit somewhere of a 250 amp charge rate, though I don’t know exactly where that’s coming from. Perhaps the BMS. I don’t know that I’d ever really NEED to charge things that quickly, but it’s cool that I can. This would charge the batteries in about an hour and a half-ish I guess.

Next Steps

Well, it’s an RV, so it’s never really “done”. So what do I plan to do now? Well, the first thing I intend to do is something with this:

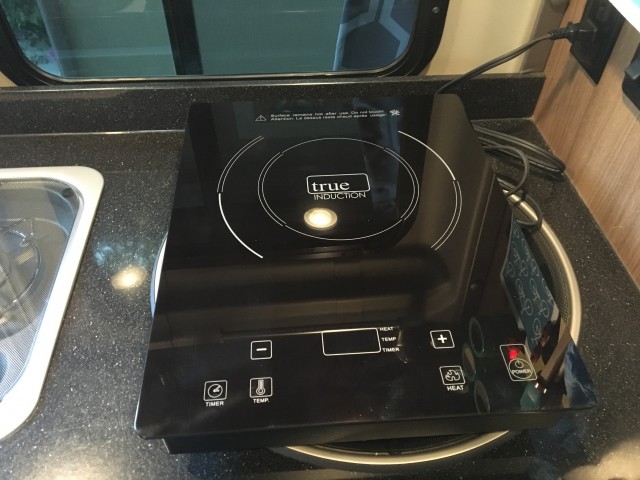

This is a True Induction cooktop. It’s the same kind Winnebago uses in some of their coaches. We’re going to have a “boil-off” of sorts, and assuming the induction cooktop wins as we expect, I’ll be mounting it up in place of the propane cooktop. Stef and I rarely use more than one burner at a time, so I doubt we’ll miss the second burner.

This cooktop is rated at 1800 Watts. That’s actually a larger load than the air conditioner if we crank it all the way up, as I did in this testing. It’s still well within the capabilities of the Xantrex inverter, so I’m not worried there. That will leave just the Truma (which is staying, for sure) and refrigerator (hmmmm… maybe…) as consumers of propane on board. Propane capacity is the limiting factor on our winter camping now, so every little bit should help.

The other thing I really want to do is to rig up something to protect the second alternator. As you can see, it sits sort of low up front:

I’m a bit worried that I may pull into a parking space with one of those cement curbs in front of it and whack it. Either that, or run over a tire snake on the freeway or any number of careless scenarios that would have me damaging the very precious second alternator. As cool as Lance’s nose ring is, I think I may have to swap it out for something more substantial that hangs a bit lower.

I’m also not too crazy about the plastic splash guard under there. I do want something there to protect from spray and particularly salt in the winter, but I’m not sure that piece of plastic is it. I also wonder what the plastic is doing to airflow around that alternator. More research needed here.

Anyway – now you know what I know. The generator’s out, and we don’t miss it, so we met objective one. And now that I’ve written this post, I’m even further down the road on the “don’t think about it” objective. Thanks for reading!

Sorry for commenting on an almost decade old thread on a rig you’ve rehomed – but a question: where did you route the 4 gauge power cable from the 2nd alternator to the coach? The Promaster is famous for having no engine compartment space.

All I can gather from your pictures is that the output cable went in front of the engine and I would guess from there back along the driver’s side…?

No worries!

And you’ve got it right. The 4/0 cable took a hard turn off the alternator, and then ran across to the driver’s side (inside the skid guard we eventually installed). Then headed back along the rail on the driver’s side.

Or at least, that’s my memory of where it ran. The battery was about mid-ship, and the inverter was in the back corner on the driver’s side on the floor, so all the heavy cable runs were along that side.

That makes sense. The frame rail is much more accessible and open on that side of the engine compartment! The passenger side is SOOOO crowded with hot pipes and accessory drives…

Grazie!

Our 2019 Travato only has certain outlets that can be used with the inverter. You mention using the AC, microwave and induction cooktop on the inverter. How did you wire these so that they can operate on shore power, generator and inverter? Is there another video that describes the wiring?

If your inverter isn’t big enough to run everything, it’s not a good idea to feed the whole circuit panel from it. You’ll just frustrate yourself by shutting down the inverter all of the time with overloads.

But for the record, it’s Shore Power —>>> inverter —>>> Main circuit panel. That’s all there is to it.

Have a Promaster based RV (2020 Pleasure-way Lexor FL). It’s lithium based with a 2kw Xantrex inverter. Looking to replace the two, 100 ah batteries with something from Lithonics. Favorite atm is their 12V 555ah F27 GTX module since it requires the external BMS which seems to be more functional / flexible. My question is specific to the wiring up through the existing MasterVolt MAC plus 12/12 50 or possibly replace it. Some talk from Lithonics sales of using the Sterling DC-DC charger instead. It would be nice to keep the generator auto-start feature after this upgrade is complete but I admit mostly from the standpoint of resale. For now, just plan to keep the air conditioner wired up for shore or generator power only but I could see that changing sometime in the future with this amount of reserved power. Anyway, any words of wisdom before kicking off that upgrade would be appreciated. Any of you recent Pleasure-way upgraders feel free to contact me on your success stories. – Retired Software Engineer.

Hi James.

We recently completed a custom van on a Promaster with a builder in New Jersey. We went with the Xantrax Freedom system and the Nations alternator. We had the alternator in our Roadtrek Zion and it would be hard to go back to something else. Due to your leak issue that others have had as well, I check the coolant constantly. We just drove it across the country and this morning I checked and it was very low. It appears the belt has cut into the hose causing a leak. It seems like these installs have very tight tolerances. Luckily I found it before driving. I have a shop appointment to hopefully fix this in a few days. I was wondering what may or may not have been done on yours to have more tolerance between the belt and hose and give some future peace of mind? Sorry for the long comment for a short question. Thanks for all your advice and tips.

Dave from CareyonVagabond

It’s been a while since I looked under there, but if I remember right, we wound up rigging up a bracket of sorts underneath there to hole the hose (the metal part that comes in the Nations kit) away from the belts.

I know others have put on “hose protectors”. I had an Amazon link at one time, but I seem to have lost it. These are like firm plastic covers that you can put over the hose in strategic places.

Every time someone goes under there to work, I get very nervous that they may bump something out of place. Just a fact of life with the ProMasters and the second alternator.

One more question – the Xantrex documentation for the Freedom SW (and all of their chargers, actually) states that they only support Flooded/Gel/AGM battery types.

It reiterates this caveat in the FAQ, as well.

Just wondering how they modified it to work with Lithium?

The folks from Xantrex helped with the programming for the Freedom SW.

What I think it means is that “out of the box”, the Freedom SW comes programmed with selectable charging profiles for lead acid, etc.

However, you can program a new charge profile with appropriate limits and voltages for lithium. That’s what the Xantrex folks did on Lance.

I believe you could do this yourself. But you’ll want to call Xantrex support and verify before purchasing.

Hi James,

One of the first things we did when we got our 2019 59G was to rip out our generator and sell it. We are looking at battery system upgrades and saw your post. Great stuff!

We are dismayed, though, that no one but the marine people are trying the LTO batteries as of yet – no thermal runaway, wide temperature range, super fast charging, up to 20,000 cycle life, etc. So, we are considering LiFEP04 now.

In any case, we were puzzled at something in your post:

“Beyond that, the Freedom SW is also a charger, which eliminates the need for the converter, and so we removed it, along with the transfer switch. ”

I am just a newbie learning about this stuff, but I thought the converter provides power to the 12v outlets and/or devices directly when on shore power and that it charges the house batteries as a secondary function.

So even if your replacement inverter charges the house battery, what about the other function the PD converter does?

Thanks,

Gaius G

The better way to think of a converter – rather than thinking of it as a charger or load support – is to think that the converter just takes 120 volt AC and converts it to 12v DC. What you do with that 12 volts is up to you.

You can charge a battery with it. You can run 12 volt loads with it. The way these things are all wired up, the 12 volts is just put “on the grid” so to speak. If you aren’t running any 12v loads, it will charge the battery. If you are running a few 12v appliances, then whatever is “left over” will charge the battery.

I may be oversimplifying for the sake of clarity, and I may have called it a charger in the write up, but that’s more or less how it works.

Just reread your post on the ‘Freedom from Generator” build. Just finished ours and it has to be the 1 if yours is a 10. Got a 2500 watt pure sine wave inverter and 12’ of 00 cable. We have the 2016 Travato 59K so there is lots of room for the inverter over the house batteries. We wanted to be able to use the microwave when we stopped for tea or coffee 9 (and heat up that pastry! ). Just have an extension cord at this point. Wanted to see what our use was. Haven’t got the induction cooktop yet but found the little electric kettle was way faster than the gas stove. In the first trip we were surprised to see how slow the van’s alternator was at recharging the house batteries. I have since read that it is really not set up for that. Your posts are so helpful with the planning of the mods I have in mind. The chart you posted showing the relationship between voltage and battery ‘fill’ is most useful. Thanks

Glad you find our content useful. And congratulations on taking the first steps toward being free from a generator!

Wonderful read. I’ve been thinking about doing this for years. But… after reading your post I’ve decided against it. The main reason is we only need this to run our microwave from 1 – 10 minutes. And after reading your post I suspect we’d have to run if for about 150 years to get some of our costs back. I am hoping that by the time our coach batteries fail (probably 2021 or so) there might be a simple cheap drop in pack which will let us draw the required 100 or so amps for that amount of time without all the other changes. Anyway, good luck on your work and may it last you for years.

Hi

I want a ALTERNATOR type of DOMETIC 3867100-01 230v 5kw 11.203.454 and Belt tensioner where I can find it ?

thank you

Let me Google that for you.

You beat me to it lol

James, I’m using your blog to help me convert a cargo trailer into a camper (strange, I know). Quick question, at some point did you do a battery upgrade? In the comments I see some references to a 7000 watt-hour battery but your write-up mentions a 420 amp-hour battery. 7000/12=583 unless I’m not understand something (or can’t do math).

Very perceptive!

(But for a lithium battery, you should be using 13.3 for a resting voltage.)

In any case, yes, we did upgrade our battery. We sent it back to Lithionics and they were able to add extra capacity to our battery. I think this happened a couple years ago now. Don’t remember the date.

But yes, we now have a 525 amp-hour battery.

Happy New Year!

I want to keep my passenger van conversion a simple plug and play. I only need to be able to run my portable air conditioner for no more than two hours in between charging the lithium battery system.

I am in the first stage of adding electricity to my van conversion. Could I use a 30 amp portable distribution power spider to charge my lithium batteries via a Xantrex 3012 converter charger?

How long would it take you to use shore power to charge your 420 amp battery? I do not want to add a second alternator and I plan to be within reach of shore power for most of my camping.

I don’t remember what the inputs to the Xantrex looked like, but I don’t think there was a “plug” on it. I believe you would have to direct wire it – and I don’t know what sort of spider you’re talking about.

I assume it could be done, but I don’t know for sure.

Regarding charge times – that depends.

You can program the maximum rate of charge for the Xantrex inverter/charger. If you had it set to 100 amps – as we do – a 420 AH battery would charge from a fully depleted state in 4.2 hours if it had full use of the charger. But that will depend on what else you’re running on the 12 volt side. AND what else you’re running on the 120v side. AND what you have shore power limited to in the Xantrex SCP. (In other words, if there aren’t 100 amps available, you won’t charge at a 100 Amp rate.)

Hi James:

I looked through the questions you were asked and didn’t see the question I have. I apologize if it has been asked. I have a 2015 Winnebago View Mdl G. I added in 500 watts of solar with a Victron 100/50 controller and a Xantrex Freedom 3012 inverter charger. About a year later in 2017, I took out the deep cell lead acids and replaced them with two 100ah Stark LiPo4 Lithium batteries. I love the way the new system works for me. I would like to know how I can go about getting the software revision you mentioned for the Freedom 3012. I used the custom menu on mine and plugged in the bulk and float parameters Stark recommended. I would love to get the software update for my Xantrex if you could point me in the right direction. Thank You

Well, I just took a quick look and was unable to find the latest firmware download.

I’d recommend you start with the phone numbers on this page and give them a call: http://www.xantrex.com/power-products-support/overview.aspx

We’ve met the support people at Xantrex, and they should be able to get you going.

If I were to replace my lead acid golf carts with the Lithium Ion Phosphate, a second alternator will be required?

I like the new type batteries, but it is a lot cheaper than doing a Volta system. And contacting them has been tough, but finally heard from them. Their system is a lot more expensive, with the 48V.

I have a Thor Aria and with the Residential Refer, does not take long to kill the leaded batteries.

Thanks.

A second alternator isn’t strictly *required*, but you won’t get everything possible out of your lithium batteries if you charge them with an alternator that is set up for lead-acid.

It’s a longer topic, but that’s basically the deal.

What about a second or third Lithium Battery??? Would it increase your ability Cool, Cook and Heat to a more usable time… Better insulation….

We actually have a 7000 Watt-hour lithium battery. How much bigger do you think we should go??!! lol.

(The current battery is a couple thousand dollars…)

Did I miss total cost data? How much was total cost of the mod?

When added as an option, a Lithium package like this runs in the $10 to $15 thousand dollar range.

First, you and Stefany have been amazing sources of information. I can’t express how much your site and posts online have helped in our research.

After a couple of years now, how do you feel that your system is holding up? I was really considering the Volta package, yet the $20K price tag, initial bugs, wait times, and such have me a little concerned. I live in the South with 2 dogs. My biggest concern is have use of the A/C while driving and for stops along the journey. After seeing the Volta option and weighing the pros and cons, picking up a rig and doing your type of build seems a bit more appealing. We drive a lot and don’t stay put for more than a night or two. What might I be missing here? I am trying to find the value proposition with the Volta, and it just isn’t jumping out yet. Thanks in advance for any guidance!

Well, to answer your first question, our system is holding up just fine, thank you. I would never consider going back.

As far as your other questions… I was just giving a “lawn chair chat” about lithium systems this past week. Here’s the main thing I told the attendees:

When you think of a lithium battery system, everyone goes mentally leaping for the air conditioner. And that’s a big part of it, but if that’s all you think about, the justification is difficult.

The REAL value of a lithium power system like ours is all the *other* things you didn’t even realize you weren’t doing because running a generator was such a pain. As in – I made a sandwich this afternoon, and I TOASTED my bread. I would NEVER have run the generator for the 120 seconds needed to toast bread. I’m in a quiet parking lot now and I’m using my laptop and it’s *charging* because the inverter is on. I would NEVER run the generator this late at night.

There are things I do every day now that I never would do if I needed to run a generator. THATS the value of a lithium system.

Thanks for the feedback and quick reply. As you point out, the ease of living with either your setup or the Volta setup is very appealing. I remain torn on the $5-!0K difference for our needs. I will keep an eye on the FB page and see if I lean more towards Volta or not as they start rolling out. At some point, I need to make a decision and move from a wannabe and to an owner!

Thank you to both of you for all that you do! It is extremely helpful 🙂

I have read through the article and most of the comments. We have a 2006 Sportsmobile prototype C on Sprinter 3500. Our 4 Deka AGM batteries are on their last legs. We also have 4 100 watt solar panels with Trimetric controller and monitor. We usually boondock but have modest electrical needs except for running furnace fan and we try not to be where we need that much heat. We are thinking of replacing AGMs with 200 to 250 amps lithium. But I am concerned with your remark that your stock van alternator would have damaged them. We don’t want to add an alternator so can we do a lithium replacement?

You *can* add the lithium batteries. Several companies market “drop-in” replacements.

You just won’t be charging them with the charging profile that they would like best.

Will it result in reduced capacity because you don’t hit high enough voltages? Perhaps.

Will it result in an overheated battery when you drive for 10 hours and the alternator is shoving 14 volts at it the whole time? Maybe.

Will it result in a reduced life cycle of say 6000 charge/discharge cycles instead of 8000? It might.

As far as I know, nobody has ever done a test on this kind of non-optimal-treatment of a lithium battery.

Bottom line is, it will work. It will probably get you improved capacity vs. what you have today. But you won’t get everything you could out of the new lithium batteries.

What an awesome in depth article! One for the archives! (Love y’all’s youtube vids too) Can you please help me have an idea; I’m relatively new at this, gonna buy a class B this year and seems like when I look at factory lithium option packages like the Freedom option from Midwest Automotive, or other factory’s add-ons, they want around 20k added to the RV price. I’m thinking/guessing a retrofit after the fact, something like lithionics/zantrex like you did would be a substantial cost, but quite a bit less than the factory option packages? Am I wrong? Can you give me a “rough idea” or rough range in your opinion what I might anticipate doing what you did? I know there are many variables, but a rough range for me looking forward? Thanks James!

If I had to hazard a rough guess, I’d say you could probably “self-build” something like this for about $13-$15k.

That’s a total un-researched, seat-of-the-pants guess.

More question than comment. I’m buying a Winnebago Era. It comes with AGM 31 batts. They are located under the coach at the very tail completely exposed to the outside weather.

What would be the advantage/disadvantage of switching to Lithium? Are they the same size? Do they shut off from charging if too hot or too cold? I just like the idea of Lithium. I would only change the batteries to have the latest tech. I have a 1000 w inverter and two 100 w solar panels with controller for the AGMs. I would just like to run the TV or compressor refer with constant worry. Is this a way to go for an old man and his toys. Any special benefit of making the change or will I lose my investment during January when we have several days of freezing weather and easy 110 deg in the summer. Lancaster, CA. Please answer by email so I have contact in the future.

Lithium batteries do not like to be charged (and even discharged to some degree) in very cold weather. If you store your rig over the winter, you may not have an issue with that, but if you use your rig, then you will be compromising the lithium batteries by storing them outside.

There are lithium batteries that are marketed as “drop in replacements” for standard sized batteries like the group 31. I have not used them, but others have with generally positive results I think.

We aren’t able to answer individual RV queries by email. But if you find a relevant post on our site, as you did here, then we can answer there and everyone can benefit from the exchange!

Dear James,

Thanks gratefully for your guidance. One major issue I have not successfully resolved is a 110F upper temperature limit on the Lithionics Battery in the South USA during the Summer.

The freezing is easy to fix with heat strips on the battery enclosure. However, cooling takes more than just a fan blowing on it from my novice understanding of thermodynamics.

As always, any guidance is greatly appreciated. High temps are a Li-ion battery-life killer. Lithionics is the most advanced, but they also have perhaps the lowest Max temperature spec as well. Rather than move to the North, I would rather switch Li-ion brands with a significantly higher Max temperature limit: unless someone could help explain why the battery specs (that no one talks about) are a non-issue.

Kind Regards.

I’ll ask, and let you know if/what I hear back.

Dear James,

What space should be allowed between the driver behind a bulkhead partition and a steel locker with:

– a 600ah li-ion battery (maybe encased in AL shell-??),

– inverter, and

– li-charger in it (with your system as a road-map)?

I notice you have a few feet with your dining table in between, and thought it may be strategic: since inverters and chargers would seemingly need a few feet space between them and Humans, going through their powerful cycles for safety sake. (Your cabin is well engineered and luxurious.)

Thank You Sir!

I am not aware of any space requirements for components. I simply put the components in the spaces I had available. I’m not really worried.

What I *would* recommend putting some thought into is SECURING the components in the event of an accident. A 200 pound lithium battery is not something you want flying around your coach!

Just found this excellent read, thanks. As you do cold weather camping, how do you prevent charging, solar, alternator, and inverter/charger from charging your lithium batteries?

Two things.

First, our battery is stored inside the heated space of the coach. So if we are using the rig, the battery is as warm as we are, which is fine for charging.

Next, the BMS on our battery will disallow charging when the temperature is too low. We don’t have to do anything for that fail-safe. It just happens.

Hey, did you ever consider an evaporative cooler?

This is, for sure, one hell of a modification. To be stored and re-read all over and over again. I wonder if you’re also an electric (electronics) engineer… One thing I noticed though, and thinking about the super duper modifications you made: on the second alternator, there are some cables (white, blue, red (?)) on sight, and pron to be scratched by the gravel or whatever. Why aren’t they covered with that rinoflex tube (is the name right?) until the alternator? This is, for sure, one so small detail, but caught my eye the minute I saw it.

God bless you people and thank you so much for your enlightenment and super awesome videos

Aerospace engineer… used to be.

I too was concerned about the whole second alternator and its wiring hanging underneath.

My solution was to work with someone to develop a skid plate for the underside of the ProMaster.

You can read about the final version here: https://www.thefitrv.com/rv-tips/promaster-alternator-coverskid-plate-the-final-version/

Got a new 2018 Dynamax Rev 24RB a few weeks ago that has many cool factory options as I know you are aware of.

I have used Sumo Springs before on my other RV as they helped but picked the heavier duty yellow ones and I should of picked the smaller ones instead for lesser weight. I like them and the did help.

So my question is that I know you used them on the back of your promaster. Which ones did you use and what is your overall opinion compared to the stock ones.

For example diesel truck passing, wind, corning, Sway etc. My wife and I love ya both. Thanks James

Mike

Meant to say the yellow sumo springs I used on my class c chevrolet were too hard on the driving up front and raised it around 2 inches. It was just too firm and not enough oscillation from the front springs since I was basically always riding on the bump stop. I should of went with the lower duty ones with lesser weight specs for load.

So the question is what was your experience with them on the promaster since my new unit is a promaster too. The promaster does come with hellwig spring dampners that work rather well over bumps as it drives like a car.

But the Sumo could and possible help with the Diesel trucks and winds. As long as it doesn’t ruin my soft ride I have now. Thanks

Think I just answered this, but we liked the yellow Sumo Springs in the back. At the time I did those, they weren’t offering a solution for the front wheels.

Since then, we’ve gone to VB Air Suspension, and there’s just no turning back.

We used the yellow Sumo Springs, and we liked them. Since nobody actually rides in the back of our van, the extra stiffness and handling was a good thing. There was no loss of comfort up front.

We’ve since moved on to VB Air Suspension – which we love!

I know this is an old post, but…have you considered taking a portable lithium battery like the Goal Zero Yeti 3000 and doing some rigging so it can quick plug-in to the RV so the RV solar panels will charge it and the Yeti can run certain items (like everything but the AC) on the circuit panel in the RV? This could power up the RV for most things and the portable battery could be pulled out and used for other things (like back-up power for the home).

That’s something we never considered.

Honestly, our Lithionics battery has all the capacity we would need.

(Our battery currently has over 7000Wh of capacity. More than twice the Yeti.)

I suppose if I were doing a self-build, I might look at something like that though.

I drive a Tesla Model S with the 100 batter. It’s truly amazing what the battery pack in this car accomplishes. Pushing the car 300 miles and heating/cooling it so effortlessly. Tesla will be releasing a semi-truck soon…hopefully that chassis can be used for motorhomes. It would be a serious game-changer not to mention less harmful to the environment.

I am currently doing a Promaster self build and have the 220 amp alternator. Could it be possible to eliminate the starter battery altogether. Charging the house lithionics battery from 330 watt Panasonic panel and the existing alternator. Then using the house Battery as a starter battery, considering how much power potential it has. This would majorly simplify things and cut down the weight.

I don’t think I’d eliminate the starter battery. You’d be interfering with the “van” part of the build, and you might compromise a warranty in the process.

Besides, usually, when you put the RV away for a while, you’ll want to disconnect the “house” battery. If there’s no “van” battery, you’d be resetting clocks and radio stations every time you hit the disconnect switch.

Hi James, we are in the process of upgrading our B class Pleasure Way Plateau XL and trying to choose the best converter/inverter to use. Our goal is to install a 3000 watt Xantrex same as yours but our installer is suggesting that it would be too loud to have inside the coach? Can you tell us how loud your inverter is?

Chris

Ours is running right now, and I can’t hear it over the refrigerator. So I’d say “not loud at all”.

Even if it was loud under load (which it isn’t), you’d be using it to power the air conditioner. We can’t hear a freight train over the sound from our air conditioner, so it could never be a problem.

Chris, could you get a hold of me? Looking to upgrade the battery on my 2020 Lexor FL and you might be able to answer a question or two. Contact James or Stephany on Facebook and they will pass along my contact information. Thanks.

Absolutely pricless amazing info….so grateful….

Thanks, Jeff! This kind of thing continues to be more and more common. This system is available on the Coachmen Galleria now (which we just reviewed).

Hi James,

My son just bought a 2018 59G and your site & videos have been extremely helpful. I’m actually thinking of buying a “K” for myself, so I have a question regarding batteries. I’m a long time sailor and on my 36′ sailboat I installed 2 extra 105 amp/hr batteries for a total of 4. If I didn’t want to get things to complicated, could I put on the 300 watts of solar panels and two extra batteries in the under bed storage box on the K and wire them all together ? This would give me 420 amp/hrs with no need to recalibrate everything for lithium. Would that work until I’m ready to undertake the lithium conversion ? Thanks!

I think the most people have generally been able to fit on top of a Travato K are 260 watts worth of panels.

Short answer: yes, what you propose would work, potentially. There are caveats though.

You’ll need to run large cable between the inside where you want to add the new batteries and the outside where the existing batteries are.

You’ll need to match the capacity of the batteries closely to what’s already there… It’s that old advice about not mixing batteries of different sizes or old and new batteries.

And the biggest caveat: if you don’t have a rig yet, you don’t know that you have a problem yet. Most people do just fine with the existing battery setup.

I’d buy the rig first, and then see if you need to do anything at all!

Hi James and Stef;

Found this post in the “favorites” column. We are converting a brand new Sprinter with the 7′ inside ceiling. Also had the same goals – no generator and no propane. I found Adam Nations and he plugged us into the Lithionics, Xantrex, Nations loop. We took delivery of all the components in 2016 and had the van finished enough to “camp” in it for family reunions last summer. But we had this system up and running! And the A/C was wonderful.

Regarding the BMS shutting off the alternator. Per Adam’s instructions, we ran a 12 VDC line, pwered by the chassis battery, to the BMS and then to the field control on the Balmar VR. If the BMS says the battery is full it opens that curcuit and the VR shuts off the field for the alternator. Incidentally, the VR also needs to see at least 12 VDC from the batteries or it won’t charge.

We also anticipated that the inverter would be a heat generator; and, since we’re starting from scratch, we added a vent pipe for that area. So the most forward of the three vents on the roof is for that. I hoped that the venturi effect while driving would suck out the heat, but put in a remote wx station to check. When it was above 90″ regularly while running the A/C, we thought that might be counterproductive; so we added a small but powerful house fan and it seems to work well.

Our conversion is taking way more time that we thought, but I’m still working more than full time and adding living quarters to a vehicle with substantial curve to the walls is time consuming.

Sure was fun to see your photos, see the similarities, and think that maybe we figured some of this out correctly.

Thanks for all your observations and articles.

Louis and Judy

Glad to hear that the system is working out for you!

It sounds like your Field Control is working the same as ours.

We’ve never done anything about the heat from the inverter as you have. Venting seems a sensible solution, and if one were building from scratch, it’s certainly worth considering. On the other hand, we’ve seen a lot of rigs from the major manufacturers with inverters, and they never seem to vent them to the outside. I’d say if you’re happy with how yours is working out, then I’d just run with it.

Hope to see you on the road!

Great work! Very helpful. One thing I didn’t see or overlooked is how you get the solar controller to switch to float when there is not enough solar current to get the battery voltage up to 14.6V. My 30A of solar (on a really good day) won’t drive my 300 AH LFP up to 14.6V so never switches to float. With typical solar I see about 20A and don’t get near 14.0V when the battery SOC hits 100% (or after it hits 100%). The result is the solar charger never switches to float and continues charging for hours beyond 100% SOC. Setting the solar controller to switch to float at a lower voltage helps, but it’s not very effective because the voltage at 100% SOC depends on the solar current which varies widely.

The LFP battery (a LifeBlue) has overcharge protection in the BMS but it’s probably the typical 16V or some such and only prevents catastrophic failure and not loss of life. And unfortunately my LifeBlue only outputs SOC via bluetooth.

Does your solar controller switch to float via a signal from the battery as do your other charge sources?

Thanks,

Harrison

I did swap my solar charge controller for a lithium-capable one from the same manufacturer. Beyond that, I did no special programming.

I do agree that a FCC circuit, similar to what is present on the alternator, would be a useful addition.

Given that we drive most every day, we’ve never had a problem with getting the voltage up. We’re 100% SOC at at least some point on pretty much every day.

Hi James. My wife and I are picking up our 2018 59G this coming week. We are carefully considering doing similar, if not the same, electrical modifications to ours.

Are the listed companies (Lithionics, Xantrex, etc) that you worked with equipped/set up to replicate your system design in another Travato? In other words, do they offer installation services or was yours a one-off install for them?

Thanks for all that you do for the RV community!

Jeff in Denver

No, at present, I am not aware that Xantrex and Lithionics offer installation services.

You’d have to check with an RV or Marine electrical specialist.

In the RV world, I’d recommend AM Solar.

James, I’m about to expose my ignorance for all the world to see but here are two basic questions I hope you will answer: First, I understand the regulator controls the volts delivered to the battery, but if your second alternator is producing more amps than the battery is rated to accept, does the battery’s BMS control that or is there a stand alone controller for the current from the alternator, or…? Second, I assume the inverter is wired “downstream” from the batteries so to speak, so how do you get those extra amps “around” the battery to an inverter so you can (for example) make coffee via the inverter while the batteries are charging?

Our battery can accept everything the alternator can put out, so no issues on that front.

Our battery and alternator also “talk”. Basically, our battery can shut down the second alternator when it’s had enough. And yes, that’s under the control of the BMS.

From your second question, it seems like you’re thinking of things connected in series – one after the other in a line. It’s not set up that way.

Things are actually connected more in parallel. So all the + and – connections come together at central points (under the dinette seat). In that scenario, there’s no controlling which current goes to where. All current flows in and out as needed, and there’s no switching.

Thanks, James. I’m working with an upfitter to build a camper van on a Promaster chasis with a system similar to yours. This helps.

Did you consider switching Lance over to 48V? It seems you had to replace many of the components anyway, and it perhaps would have allowed you to use much of the existing wiring instead of having to rewire much of the coach. Also, the wiring from the new alternator could have been smaller, saving much weight, right? With everything I’m reading about 48V systems, it seems like a no-brainer, but perhaps I’m missing something.

Thanks for all your info – all good stuff!

It’s true that 48V does save some weight on the wiring.

We didn’t consider it at the time.

We still would have needed to run wiring between the second alternator and the coach battery. And between the coach battery and the inverter. And between the battery and whatever was converting the 48v to 12v. And we would have needed to change the programming on the solar charge controller to charge a 48v battery – which probably would have required a different controller altogether, since the panels don’t even natively put out 48v. And we would have lost the capability I have to temporarily connect the coach and chassis electrical systems. (This can come in handy when you want to charge the batteries in a big hurry – I’ve got two alternators!)

Anyway, if I was doing it again now, I might consider it. But as a retrofit, it’s quite a bit of work.

Thanks for detailed write-up James. It seems that an efficient 12V DC A/C would make it a lot easier to size a system like this reducing the battery and inverter load. Every RV A/C on the market here is designed for shore power. I’ve seen a Chinese brand of bus/van 12V A/C units that looks promising at providing off-grid A/C… but I haven’t seen anyone actually test or review it.

The problem with the 12v AC units is (just my opinion here) the size of the cable you would need to run to them in order to both provide enough power to get to 13,500 BTU and to overcome the voltage drop. You’d be running 4/0 cable.

Certainly not impossible, but kinda big and heavy cable. I’ve seen that Chinese unit, but never seen one in person. If they want to send me one to test, I’d be happy to!

Yeah, I guess there’s never a free lunch! Would have found you and said hello at the Hershey RV show, but I was there early and left early, so I missed you guys. Man – those shows are exhausting. Don’t know how you do it. 🙂

The other problem with 12v AC is equipment cost. I just finished researching this and self contained all electric roof mounted systems from reliable manufacturers start at around $3800.

That’s more than three times greater than a typical RV air conditioner!

That was great. Thanks, James. We’re picking up a travel trailer this week and I’m looking at long term options for ditching a generator as we rarely, if ever, dry camp/boondock. Lithium Ion is only going to get better over time and your information is very helpful.

Enjoying your videos too. Thanks for all your great work.

Agreed, and if you rarely boondock, you’re a good candidate for ditching the generator.

(You’re NOT a good candidate for solar though…) 🙂

Enjoyed reading through writeup and comments.

We have 1400 W of solar and 9 kW-hrs of LFP on 5th wheel. We can run standard Dometic a/c for 4.5 hours with full sun and down to 50% SOC.

We have 415 W of solar and 4.5 kW-hrs of LFP on Roadtrek. We can run smaller Dometic a/c for about 2.5 hours with full sun and be down to 50% SOC. We can run down to 20% but choose not to.

Reed and Elaine

Impressive.

What brand of air conditioners are you running?

Dometic power hogs (2200 W for 5th wheel and 1200 W or so for the Roadtrek)

Would go to mini-split but we are Goldi-lockers, and go to where it is neither to hot, nor to cold, just right. So Mexico for winter and Canada/high mountain (7000′ and higher) mountain west. Air conditioning is something we seldom need even in Yucatan; however there can be hot spells. It was 103 going north near Merida a year ago. We were to Puebla (8000′) two days later. Just running for half an hour can really reduce cabin temperature. The 12 V fans (plug into the numerous cigarette type outlets) only use 10 W (about 1 amp at 12 V) and make a great difference in comfort level.

We do have a 1 kW Honda generator in a box at back of 5th wheel which we need to take out and run for an hour or so. The Roadtrek has an integral 2.5 kW Onan (runs off vehicle gasoline) that we used once in Newfoundland and once in Mexico. 90% of usage has been monthly half hour runs as suggested in manual.

We are currently mootchdocking at older son’s place at 7600′ in mountains NE of Las Vegas, New Mexico. Night time temperatures are in low 50s and daytime are in mid 70s. It rains every afternoon: second or third wettest summer since 1941 for New Mexico.

Reed and Elaine

Does the additional alternator under the hood rob the engine of a lot of power and does it greatly change the gas mileage?

Nope and nope.

1 horsepower is about 750 watts. SO even if the alternator produced 3750 watts of charging (which it never has), it would only be 5 HP.

It’s a 300 horsepower engine in Lance! It’s less than 2%.

We haven’t noticed anything. Plus, it charges so quickly that it shuts itself off after a while on long drives and there’s really not much load after that.

Hi again James. Having been unable to find a better place to leave this comment, hopefully it’s okay to be sort of on topic, but not really. Anyway… I just watched your Aug 14 video with Mike Neudorfer of Advanced RV (excellent work as usual!) and was blown away when he said they had been running the A/C on the van with their new 48v electrical system for 7 hours at “full 100% duty cycle” and the batteries still had 94% capacity remaining. Unlike some people I could mention I’m no rocket scientist (I do well to remember basic algebra) but after taking a stab at the math I think that means the battery bank would need to be about 3200aH. Did I calculate that right? And if so, can that really be what Advance RV is putting in their vans? Or did Mike fail to mention the alternator was running part of the time, or whatever?

3200 AH would be a massive battery bank. And I didn’t ask how large the one we were looking at was. (I know, I know… I should have)

But I think we would need to add a zero… even to that number.

Assume the AC is 12 amps at 120 volts. That’s 120 amps at 12 volts. (*10)

120 amps for 7 hours is 840 amp hours. And if that’s only 6% of the battery capacity. That means the whole capacity would have to be somewhere around 14,000 AH.

Which would be huge! So, realistically, I think they drove home, or ran the engine at some point.

What I think this reflects – more than anything – is that by having a battery system with sufficient capacity and capability, they just don’t really think about it very much. They just let it do its thing and don’t worry about it. “Did we drive? Uh… Maybe. Yeah, I think we may have driven? Marcia – did we drive after we turned the air conditioner off?”

That’s kind of how I imagine that playing out in an Advanced RV owner’s head. They just don’t keep track of that kind of thing because it’s become unimportant.

My two cents, anyway. Next time I talk to Mike, I’ll try to get some more specifics.

I was thinking 3200aH or so since it’s a 48 amp system, right? But either way a lithium bank big enough to run the A/C for 7 hours without charging would be crazy expensive…like $50k or more I would imagine. I know that’s not out of the question at the prices Advanced RV charges for a new build, but still… Wow.

It would be interesting to know what capacity that van really has. Please do let us know if you find out.

You make a good point about a system being so well designed that it’s not on the user’s radar. If the system does what it’s designed to do, even a tech savvy guy like Mike could lose track of the metrics. Which would be pretty wonderful.

derp… 48 volts…

You got me. Yes, it would be a 3200-3500ish, 48 Amp Hour battery. It would still be massive, I think. Bigger than what I saw underneath the van.

But I really do think the tech eventually becomes a non-thing for them.

Kind of how like I have no idea what pressures exist in my vehicle’s exhaust system.

I mean, yes, technically, they could affect my mileage. But meh…

Hi again, 125 comments later I’m late to the party commenting today as I re-read just now (honestly scanning and absorbing best as possible the scientific details) today…Thanks for the deep dive into your lithium upgrade. Brenda and I do have an appointment upcoming at AdvancedRv to meet with them about upfitting our battery system and front seats. FitRV’s website content (your work) is a treasure and inspiration. Thank you, Dave

The crew at Advanced RV will steer you right. They’ve been at this a while!

And while you’re there, tell them we said “Hi!”

Hi again James,

We’re a little closer to finalizing our LiFePo4 setup on our yacht and your article has been a great asset as we move along in the process. We need a few more decisions to be made around how to manage our charging/load bus bars, but making progress.

I have another question / comment for you. You mentioned in the article that “On the charging side, when the Xantrex is plugged in, it delivers its programmed 100 amps to charge the battery.” The 3012 is capable of 150A @12VDC charging (I’ve seen it easily on our current AGM setup many times). Have you specifically limited the charging side of the unit to 100A for a specific reason, or are you possibly running a different model than the original?

Derek

The 100A limit was something suggested by the Xantrex guys when we did the install.

In my mind, 100A at 12v is about 10 of our 30 available AC amps. That still leaves us plenty of overhead for air conditioner, etc.

(Yes – it’s true that I could throttle the shore power down as well to make sure I never trip a breaker, but in case I forget.)

Also – I’m never worried about charging that quickly if I’m plugged in.

If I’ve bothered to hook up the shore power, we’re staying a while and the extra quick charge isn’t as big of a deal.

Thanks for the reply. That approach makes sense if you have those limits, and as you’ve said, if you can pump 100A continually into the lithium, that’s huge power anyway. We do the same sometimes when running the generator with all A/C running and such as we don’t need the charger pumping full power. It is interesting that with the Xantrex you can change this on the fly with the 2nd screen on the SCP varying from 5A-30A.

Again, thanks for the reply and insight.

Derek

Right on. Good luck on your yacht project!

Hi James,

Thanks for sharing such a detailed report of your undertaking. I’m coming across your post as we’re looking at a yacht based LiFePo4 setup with existing Xantrex charger/inverter, 1.1Kw of solar, and dual 80A alternators and 3 onboard AC units. Same but slightly different to yours, however overall system design will be pretty close.

Quick question — what firmware do you have installed on your Xantrex now?

Thanks! Hope your system is as trouble free as ours it.

Our SCP shows Firmware 3.06.00 BN3.

Thanks for the quick reply. It appears you’re one or two up on us — we’re 2.03.00 BN3 for the FSW30 and 1.03.00 BN2 for the SCP specifically.

Do you have the contact at Xantrex or process that might be able to help us with an update by chance?

No specific contact. I’d suggest just calling their customer service.

Those folks should be able to help you.

Hi James,

First thanks so much for your and Stef’s informative and entertaining reviews. It makes a very meticulous and tedious process of searching and purchasing an RV more fun. My wife and I are entertaining the thought of purchasing a 2017 Travato 59K. We are confident that we will need an Auto Gen start mechanism as from time to time we will be leaving our dog unattended in warm weather and we are not yet prepared for the full Lithium battery overhaul. Per the link provided it appears that you had installed at one point a MAGNUM MEAGSN. The other model I have been looking at is the EC-30W. One good selling point is that I am not great at complicated DIY projects and this seems easy to install. If you are familiar with the EC-30W is it possible to provide some pros/cons between the MAGNUM and ED-30W? If not, can you provide just the pros and cons of the MAGNUM?

Again, thanks so much for the entertaining reviews.

The only auto-gen-start I’m familiar with is the Magnum, so I can’t provide any kind of A/B comparison.

If the EC 30 is the model I’m thinking of from Onan, it should install with a minimum of fuss. You will have to crawl underneath to install it.

Wincrasher wrote something up on his blog about that install. Ron is a thoughtful guy. You can read about his install here: http://wincrasher.blogspot.com/2015/05/onan-generator-remote-control-ec-30w.html

I am planning on doing the same on my 59K but was wondering if Xantax / Zamp would help anyone (not famous folks)with a similar project . If so, do you know what are the fees / cost.

I don’t know if they do for-hire consulting. But your best bet would be to call up their customer service number. Those folks are super helpful and can get you started out.

James, I’m very grateful that you took the time to write this up. It’s fun to read, and after hearing about the many problems Roadtrek owners have had with their system, and seen the price tag on Advanced builds, you’ve given me renewed hope that my wife and I might be able to achieve our goal, which is to power a production class B van’s air conditioner with batteries all night while we sleep.

You wrote that your AC runs about 3.5 hours with a 100ah battery, so I’m thinking we should rig up something that would automatically start and stop the engine through the night as required to keep the battery charged (similar to Roadtrek’s “volt start”. Do you have any thoughts or suggestions on a way to make that happen? Also, assuming we can find the room, what do you think about a larger battery bank, say, 300ah? Would that take too long to charge back up?

Thanks!

Our AC ran for 3 hours and 19 minutes with a 420AH battery.

So to get through the night, you’d need at least twice that, and probably a little more. Maybe 1000AH.

If I had to guess what’s in a “voltstart” system, I’d say they took a standard auto generator start and spliced it into a remote car starter. :-p

I guess what I’m saying is, the electronics to make that work aren’t terribly complex, and the solution is out there: it’s just in two different products.

Thanks for that fast reply James. I was already wondering if the Xantrex generator automatic generator start device paired with a remote engine starter might do the trick. It’s encouraging to have someone with your level of knowledge confirm that as a likely solution to pursue. And again, thank you very much for taking time to post this information in such detail. This is a real gift to the RV community which will be greatly appreciated for years to come.

Thanks! If you do go that route, and get it to work, please post back!

Hi James,

I read the whole article and looked at every picture – that says a great deal about how well and how clearly you write. I could follow along and understand what you were talking about even though I am completely clueless about batteries, power, wiring, and well… vehicles in general. I’m not saying I totally grok it all. I couldn’t remember any of it once I was done, and would have to re-read it several times and read up on how batteries work, and what the difference is between the types of batteries you mentioned, but just had to give you props for writing it all so clearly! Food for thought when I am ready to start nomadding… though it’s a long way off from now. Thanks!

Wow. Thanks, Diane!

I usually ask Stef to read my posts for a “non-geek-check”. That probably helps a lot, so props to Stef. Good to know we’re keeping it sane!

Did you think about putting in a Lithium Battery for the chassis and then adjusting the stock alternator to be able to charge both the chassis and the coach?

I know that would cause some issues in the cold, but didn’t you think about how to keep them warm before they were mounted in the coach drawer area anyway?

Honestly, I never really thought about doing that. There’s no reason why it absolutely won’t work, but a couple problems you’d need to overcome.

First – I’m not sure how many amps of charging are left over with the stock alternator, but it’s probably not the 180 ish that I can get from the second alternator. You would have to anticipate longer charge times due to fewer amps available.

Second – I’m not sure how to change the charging profile for the stock alternator. But let’s assume there’s some sort of external voltage regulator you could get. Even if you did that, you’d be taking a gamble that all the other electronics in the vehicle would be OK with the different charging profile. Not sure how to verify that, but probably a call to Fiat would have been required.

Finally – the freezing thing, as you’ve alluded to. For our house battery, that’s just inside the heated space of the vehicle. I can warm that up before engaging the house battery at all, so that’s fine. But the chassis battery has to be available all the time or I can’t even start the vehicle. Also, it hangs down below the floor under the driver’s feet in the ProMaster. No real way to keep it warm, and I would have had to engineer a separate solution for warming the vehicle without starting it.